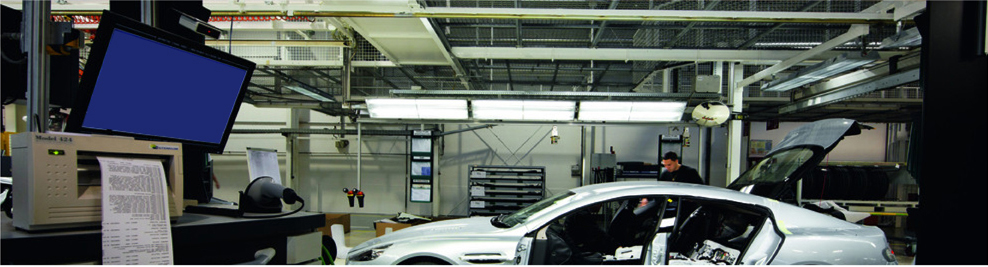

GS700MW Mercedes/BMW booth

|

|

GS700MW Waterborne Mercedes booth(PLC control)

|

|

Inner Size |

7000*4000*2900 mm(L*W*H) |

|

Outer Size |

7120*5670*3650 mm(L*W*H) |

|

Main Door |

3-fold, 3000*2800 mm(W*H), |

|

Personnel Door |

1 unit, 800*2000 mm(W*H), |

|

Booth Cabin |

Wall panel:60mm ROCK WOOL insulated panels, 0.6mm color steel sheet, tongue and groove structure (color:blue, orange, white) Roof panel:single layer galvanized sheet, Booth cabin with aluminum frame. |

|

Basement |

Galvanized steel basement, 300mm high. Two pcs outer ramps, each size L2000*W750*H295 (inner ramp optional). Full floor grills, 5 rows (30*5 flat steel). |

|

Lighting |

Ceiling lights: 4*36W*8 units, Side lights: 2*36W*8 units, electronic ballast. Illumination: 1200 lux. |

|

Air Unit |

Aluminum frame, colored steel sheet unit panel. (Air unit position option: left, right, rear) |

|

Air Exhaust |

YDW 7.5kw centrifugal fan 1 unit, air capacity: 21000m3/h, 2 straight air duct and 1 elbow duct, 1 electrical air damper duct. |

|

Air Intake |

YDW 4kw centrifugal fan, 2 units, air capacity: 25000m3/h |

|

Air Filtration |

Air intake flat pre-filter, ceiling fine filter, exhaust with glassfiber filter and “M” type carbon filter |

|

QAC System |

Quick air curing system (QAC) for water-borne paint, with 2 extra blowers, 2x1.5kw, air capacity 6000-10000m3/h, adjustable quick air nozzles 24 pieces. |

|

Heating |

Riello RG5S diesel oil burner, heat capacity 260000 kcal/h, stainless heat exchanger, max. drying temp. 80℃. Pneumatic cycle damper from spraying to baking. |

|

Control System |

PLC control, Inverter, Lighting, Heated spray, Normal spray, Baking, Temp. setting, Time setting, Power supply switch, Emergency stop. All majorly Siemens/ Schneider parts |

|

Power |

17.5kw(spray cycle), 7.5kw(bake cycle) |

The full

tempered glass door (optional)