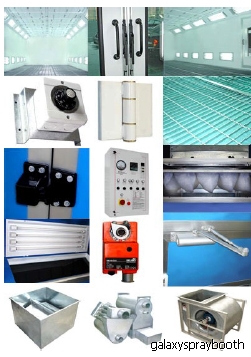

GS100

Dimension

Outside:7000×5356×3400mm(L×W×H)

Inside: 6900×4000×2650mm(L×W×H)

Basement

Galvanized steel assemble, 300mm high, base cross and longitude beams made byquadrate steel

Three rows of checkered plate, surface paint, two rows grids ,4X30mm flat and twiststeel welding(Full grids is optional), zinc plated

2 embossed steel ramps, 2000X600mm(LXW)

Room Body

Sandwich type wall panels, 0.476mm thickness, colour steel with 50mm thick EPSinsulation inside;

galvanized steel roof plates.

Front Door: 3000×2600mm(W×H), 3 folds. Escape Door: 800×2000mm (W×H).

5mm thick clear tempered glass windows.

Ceiling Parts: galvanized steel assemble, powder coated. C-shape ceiling filter holders, powder coated.

Generator Setting

Steel frame, covered with galvanized color steel

Intake Air System

1×5.5KW turbo fan, total air capacity is 22000m3/h

Heating System

Italy RIELLO G10 Diesel burner, SUS304 stainless steel heat exchanger, heating productivity: 100000Kcal/h. Heating change efficiency≥85%.

Pneumatic damper, stainless duck(1meter).

Exhaust Air System

none

Filtering System

Pre-filter (pocket style), 600G high efficiency filter (ceiling filter), floor filter (fibreglass), activated carbon filter (pocket style).

Lighting

8 x4=32x36W inclined ceiling lights.

Electronic ballasts, Philips tubes. Illumination≥1000Lux.

8 x2=16x36W inclined wall lights

Control System

Relay control for spraying, heat spraying, baking, lighting switch, baking time,temperature setting, hours meter, emergency stop, pressure gauge

Total Power

7KW

Inner ramp (optional), square observation window(optional)

Booth Color:White color(optional: Blue, Red, Orange)